Mayan Porter

Recipe Specifics:--------------------------

Batch Size: 5 gallons

Total Grain: 12lbs 14oz

Starting Gravity Estimate: 1.061

Anticipated SRM: 31

Anticipated IBUs: 43

Final Gravity Estimate: 1.016

Brewhouse Efficiency: 65%

Wort Boil Time: 60 Minutes

Grain Bill:

--------------------------

9lbs Maris Otter Pale Malt (3 SRM)

1lb Brown Malt (65 SRM)

1lb Crystal 60L Malt (UK 55L)

1lb Victory Malt

8oz British Chocolate Malt (450L) *see note 1

4oz Carafoam

2oz Crystal 120L Malt

Hops, etc.

--------------------------

1 oz Wye Challenger (60 min boil)

0.5 oz Columbus (30 min boil)

1 tsp Irish Moss (15 min boil)

0.5 oz Amarillo gold (10 min boil)

125 gm Cocoa Powder (Dutch process 15% cocoa butter)(5 min boil)

12 gm Cinnamon, ground (1 min boil)

12 gm Chipotle Chili, ground (1 min boil)

Yeast

--------------------------

White Labs WLP002 (1000ml starter)

Water Profile

--------------------------

RO water *see note 2

To 4 gallon mash water added:

3 gm Chalk

1 gm Gypsum

3 gm Calcium Chloride

2 gm Epsom Salt

7 gm Baking Soda

To 5 gallon sparge water added:

4 gm Chalk

1 gm Gypsum

4 gm Calcium Chloride

3 gm Epsom Salt

9 gm Baking Soda

Mash Schedule

--------------------------

90 min Saccharification rest at 154 F

mash out at 168 F

My usual process is to add the mash water to the mash tun and start circulating it through the heat infuser to obtain the desired mash temperature. Once the temperature is achieved the milled grain is added, and the circulation continues as the grain becomes

submerged and the heat infuser cycles on and off to maintain the proper mash temp. I also conditioned the malt prior to milling which is how 12 lbs of grain looks more like 18 lbs. I also added the mash water minerals to the milled grain and not the water. I use these minerals as flavor adjustments and still use Five Star 5.2 pH Mash Stabilizer to ensure proper pH for enzymatic action.

submerged and the heat infuser cycles on and off to maintain the proper mash temp. I also conditioned the malt prior to milling which is how 12 lbs of grain looks more like 18 lbs. I also added the mash water minerals to the milled grain and not the water. I use these minerals as flavor adjustments and still use Five Star 5.2 pH Mash Stabilizer to ensure proper pH for enzymatic action.Today, once the grain was completely submerged and the mash tun had stabilized at 154 F, I shut the circulation pump off and closed the valves on the mash tun. For 90 minutes I watched the temperature of the mash remain stable at 154, maybe dipping to 153 by the end of the 90 minutes.

After 90 minutes, I restarted the pump and set the temperature objective to 168 F for “mash out”. Realizing that part of my objective was to reduce any scorching of the wort by the heating

element, I also limited the high output of the PID to 75% (it has always been set to 100%). At the same time, I am heating the sparge water (5 gallons) to 168 F. After achieving the 168 F in the mash tun, the first running of sugary wort are trickled slowly into the kettle. I had been doing this at the limit of the grain bed, emptying whatever had arrived at the grant. After some reading I re-discovered that draining the grain bed quickly can significantly reduce efficiency.

element, I also limited the high output of the PID to 75% (it has always been set to 100%). At the same time, I am heating the sparge water (5 gallons) to 168 F. After achieving the 168 F in the mash tun, the first running of sugary wort are trickled slowly into the kettle. I had been doing this at the limit of the grain bed, emptying whatever had arrived at the grant. After some reading I re-discovered that draining the grain bed quickly can significantly reduce efficiency. Based on my not-so-scientific observations, the combination of conditioning the malt, paying close attention to temperatures and

the speed of runoff and by the observation of some of the remaining grain husks, It appears as though all of the starch was converted. The husks shown here in my hand appear completely intact. In reality they are completely empty with only the small kernel of germinated barley left in the tip of the grain husk. This means a better filter bed and more complete conversion of starches to sugars (I hope).

the speed of runoff and by the observation of some of the remaining grain husks, It appears as though all of the starch was converted. The husks shown here in my hand appear completely intact. In reality they are completely empty with only the small kernel of germinated barley left in the tip of the grain husk. This means a better filter bed and more complete conversion of starches to sugars (I hope).My pre-boil gravity (measured in Brix using a refractometer) was approximately 1.044 and I had roughly 6.5 gallons of wort. I’m sure somebody has a way to calculate evaporation rates by measuring pre and post boil gravity, but I haven’t looked yet. All this measuring and calculating are not part of my normal brew day, but I am trying to understand where the inefficiencies in my PAWS brewery are. Once I know what they are, I can attempt to remedy them or compensate for them if they are not financially feasible.

The boil schedule went as expected with a minor flaw; my kitchen timer got wet and died. I had to improvise by using the kitchen’s kitchen timer which was not partially melted from propane burners and hadn’t had wort splashed all over it so it wasn’t sticky.

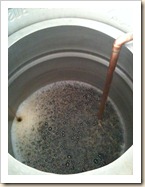

The boil schedule went as expected with a minor flaw; my kitchen timer got wet and died. I had to improvise by using the kitchen’s kitchen timer which was not partially melted from propane burners and hadn’t had wort splashed all over it so it wasn’t sticky.After the boil is where the latest addition to the brewery is utilized. I added that new temperature probe I mentioned previously and installed a T-fitting after that. One side of the T is for the Oxygen stone and the other goes to a whirlpool arm (see copper pipe in picture at left) that I

fabricated out of some copper pipe. So, whirl-pooling the wort as it chills through the Blichman Therminator serves two proposes; to eliminate cold-break from my fermenter and to ensure that the wort is uniformly cooled as much as I can. Once the wort was chilled to 73 degrees F, I cracked the valve on the Oxygen cylinder, through a HEPA filter and into the whirlpool. After a few minutes, the line was switched to the 6.5 Gallon glass fermenter.

fabricated out of some copper pipe. So, whirl-pooling the wort as it chills through the Blichman Therminator serves two proposes; to eliminate cold-break from my fermenter and to ensure that the wort is uniformly cooled as much as I can. Once the wort was chilled to 73 degrees F, I cracked the valve on the Oxygen cylinder, through a HEPA filter and into the whirlpool. After a few minutes, the line was switched to the 6.5 Gallon glass fermenter. Keeping this close an eye on the entire process was painstaking work and basically proved nothing. I still hit very close to the predicted 65% extract efficiency with an Original Gravity of 1.060 (from calculated 1.061) which is very close to predictions. If I was satisfied with achieving 65%... Although this is common extract efficiency for home brewing, it would never be financially viable on a commercial scale and in my narrow minded view, if 90-100% is an “A”, 65% is still a “D” grade. At least it’s not an “F”, right?

Keeping this close an eye on the entire process was painstaking work and basically proved nothing. I still hit very close to the predicted 65% extract efficiency with an Original Gravity of 1.060 (from calculated 1.061) which is very close to predictions. If I was satisfied with achieving 65%... Although this is common extract efficiency for home brewing, it would never be financially viable on a commercial scale and in my narrow minded view, if 90-100% is an “A”, 65% is still a “D” grade. At least it’s not an “F”, right?Remember from the Manchester Ale Yeast post that I had to invoke Plan B and use White Labs WLP002 yeast. The good news is that I had almost 2 weeks to propagate the yeast colony to a full liter of starter solution. After

using a Neodymium magnet to fish out my stir bar, I poured the entire liter into the fermenter (I did not think to let the yeast settle out in time). Within 12 hours, I had a minor (1/4 inch) krausen going and by 6pm on Sunday, a full inch of foam with little volcanoes of cocoa/chili/cinnamon coming through the top. I’ll have to post later on any tasting notes for this experimental batch.

using a Neodymium magnet to fish out my stir bar, I poured the entire liter into the fermenter (I did not think to let the yeast settle out in time). Within 12 hours, I had a minor (1/4 inch) krausen going and by 6pm on Sunday, a full inch of foam with little volcanoes of cocoa/chili/cinnamon coming through the top. I’ll have to post later on any tasting notes for this experimental batch.Note 1:

I have just realized in writing this entry that the elusiveness of the original Pedigree Porter recipe, that I have been trying to recreate for 3 years may be in the differences between British Chocolate Malt and American Chocolate Malt. The main difference is that British Chocolate is 100 degrees L darker than American and the flavor profile is different. American Chocolate is listed as:- Chocolate malt will give your beer a warm, nutty, chocolate-like flavor. Just a few ounces in a batch will impart a slight brown color. Use up to a pound in porters and stouts and dark lagers.

- British chocolate malt offers deep colors without the roasted edge, roasted with premium British malts.

No comments:

Post a Comment